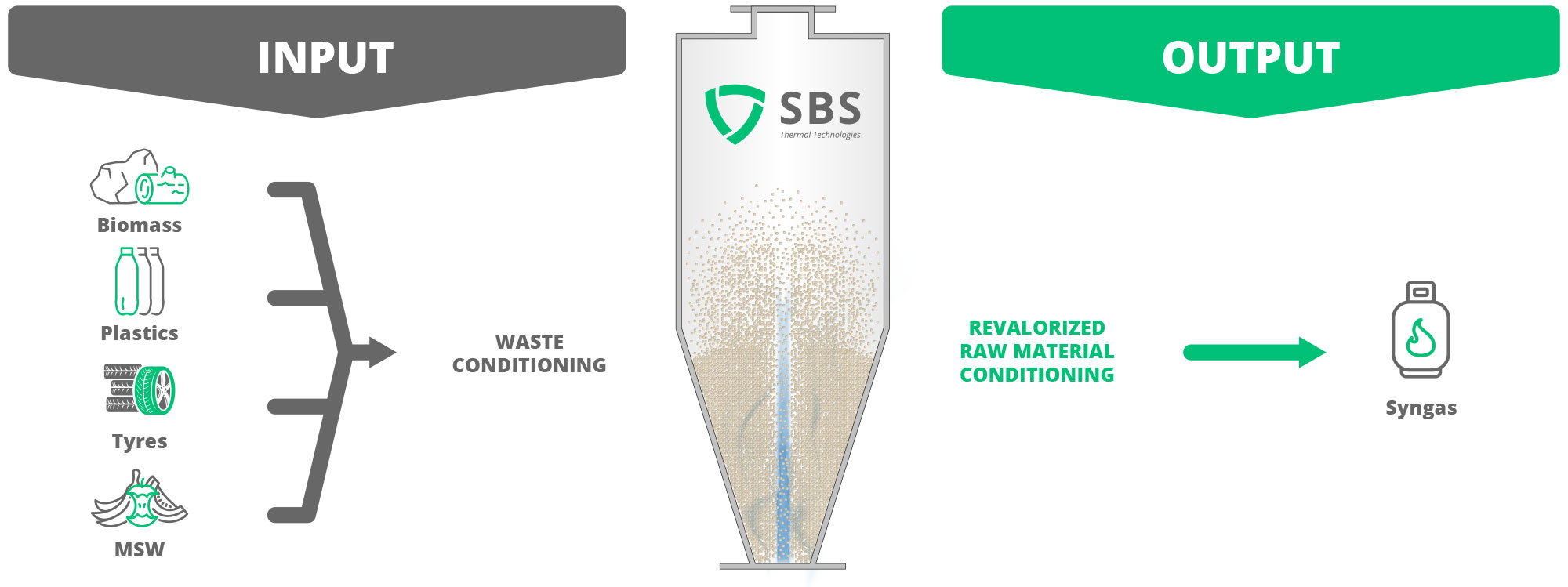

Gasification

Gasification turns solid or liquid raw materials into gases that can subsequently be used as fuel or in production processes for other elements. One of the most useful products that can be obtained via gasification is synthesis gas, usually known as syngas.

HECO technology helps overcome the limitations of the physical phases prior to gasification and facilitates the volatilisation of pyrolysis products. This is a key point, as it makes this phase prior to pyrolysis and cracking more effective, which in turn enhances the effectiveness of the whole process of gasification and reformation of volatiles in gaseous form. The high rate of transfer of heat and material from one phase to another, the absence of temperature gradients, the low holding time and the absence of bed fluidification enables faster volatilisation and minimise char and tar.

Biomass gasification

Biomass gasification is a process that turns biomass- and fossil-fuel based materials into gases. This is done by getting materials to react at high temperatures without combustion, controlling the amount of oxygen and/or steam present in the reaction. Gasification has the advantage that using syngas can be more efficient than burning the original infeed material directly, because it can be burned at higher temperatures.

Plastic gasification

One of the main chemical recycling processes involves heat-treating plastic waste. The inevitable shift in the global energy paradigm from a carbon-based economy to one based on hydrogen has revolutionised the capabilities of heat treatment processes. This applies especially to gasification and pyrolysis. Indeed, recent technical research into new ways of managing municipal solid waste reveals that a combined gasification/pyrolysis technique is more energy-efficient and environmentally friendlier than other processes.

In general, extracting energy from a solid carbon source via gasification involves two simultaneous or competing reactions: pyrolysis and gasification per se.

Gasification of tyres

Gasifying tyres involves more phases than pyrolysis, and comprises heterogeneous and homogeneous reaction mechanisms. During the heterogeneous reaction, chemical reactions take place on the surface of the material. As a result, the conversion rate depends largely on factors such as the surface area, ease of access to the surface, active carbon sites, the concentration of inorganic material and the composition of the gasification agent.

Gasification of various raw materials has shown great potential for producing high-quality syngas. However, conventional gasification systems have not been developed so as to efficiently reduce the substantial amounts of energy needed to break down the infeed material.

MSW gasification

Gasification produces more energy per tonne of waste than incineration.

The main reason why MSW gasification is becoming more widespread is growing discontent in technical and environmental circles and among the general public with the use of conventional incinerators.