Drying

The goal of eliminating excess moisture content in materials is to reduce the cost of transporting them. This can be done in various ways, but heating is the only way to ensure compliance with the strict specifications to which end products and intermediate products are subject.

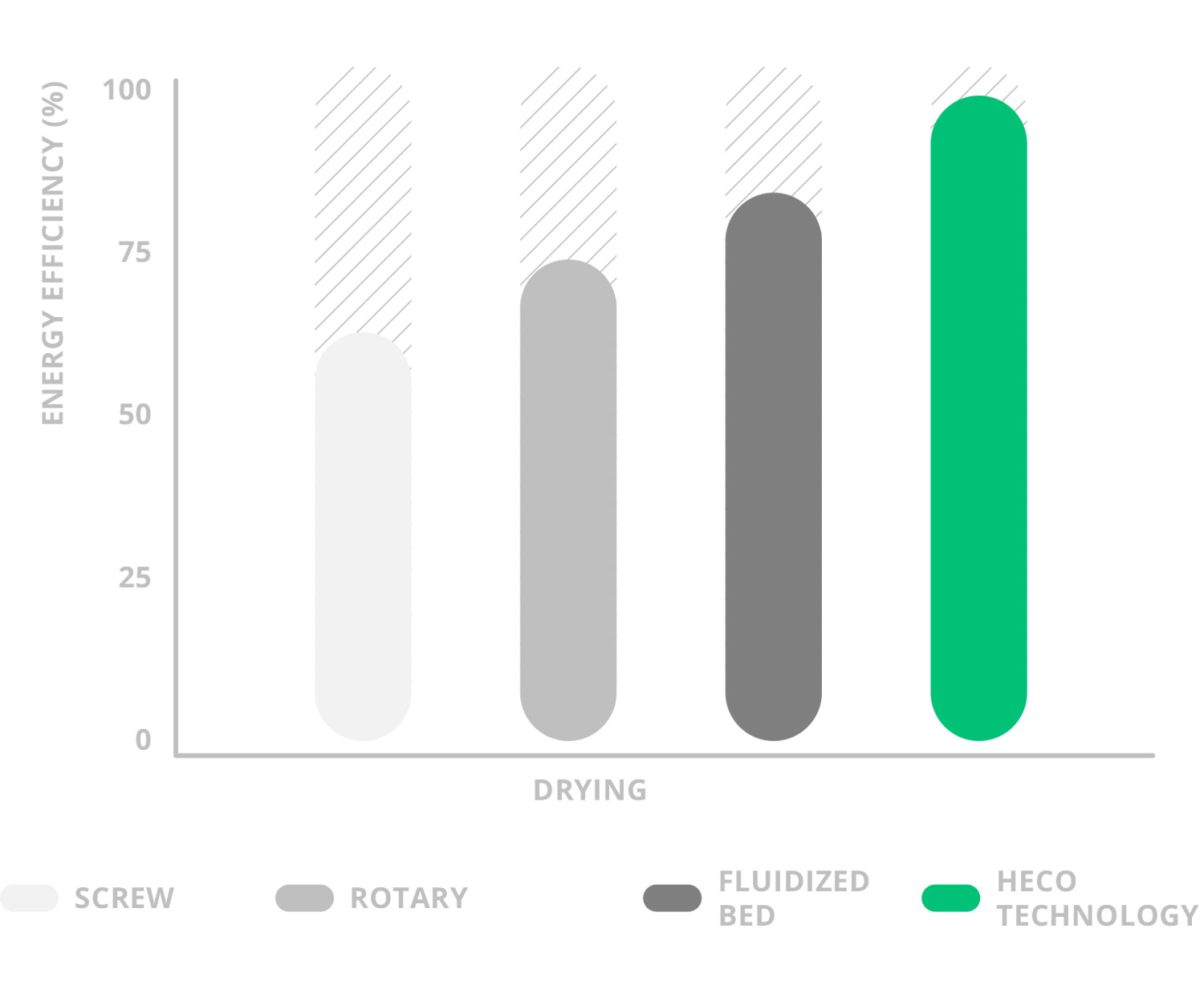

SBS’s HECO technology provides high-efficiency (>95%) drying, which means substantial energy savings compared to other technologies. This may result in process costs being as much as 40% lower.

HECO technology vs conventional drying technologies

Industrial minerals

Minerals separation processes generally entail using substantial quantities of water that must then be eliminated using a battery of processes organised in series. Heat drying is the last operation carried out at the plant. Its purpose is to reduce transportation costs.

Drying with HECO technology is suitable for many different types of aggregates, whatever their original moisture levels, and provides an end product with a moisture level of less than 0.1%. The high energy efficiency and simplicity of the plant required means that production costs are lower than for other technologies on the market.

Agroforestry products

Drying agroforestry products makes them cheaper to transport and also helps assure their quality and conservation by eliminating the possibility of fungi that could rot them. The heating properties of forestry waste for use in biomass combustors are also improved if the waste is dried.

HECO technology offers solutions for various types of agroforestry products, whatever their original moisture levels. Along with cost savings of up to 40%, HECO technology features intermittent contact with materials, so sensitive materials such as grain can be dried at higher temperatures without affecting their quality.

Foodstuffs

Drying or dewatering has always been one of the best ways to preserve foodstuffs, extend their lifetimes and facilitate their storage, transportation and handling.

Our high-efficiency solution can dry or dewater foodstuffs while maintaining their original size, and can also convert them into dehydrated powder form. Our intermittent drying process prevents the loss of nutrients in the products, and the cyclical movement produces ready-to-use compounds.

Urban & industrial sludge

Industrial sludge is a production process waste with high moisture contents. It may also have a high organic content. Sludge treatment plant is a by-product of waste-water treatment that concentrates the contaminants eliminated from water. It needs to be dried for subsequent treatment.

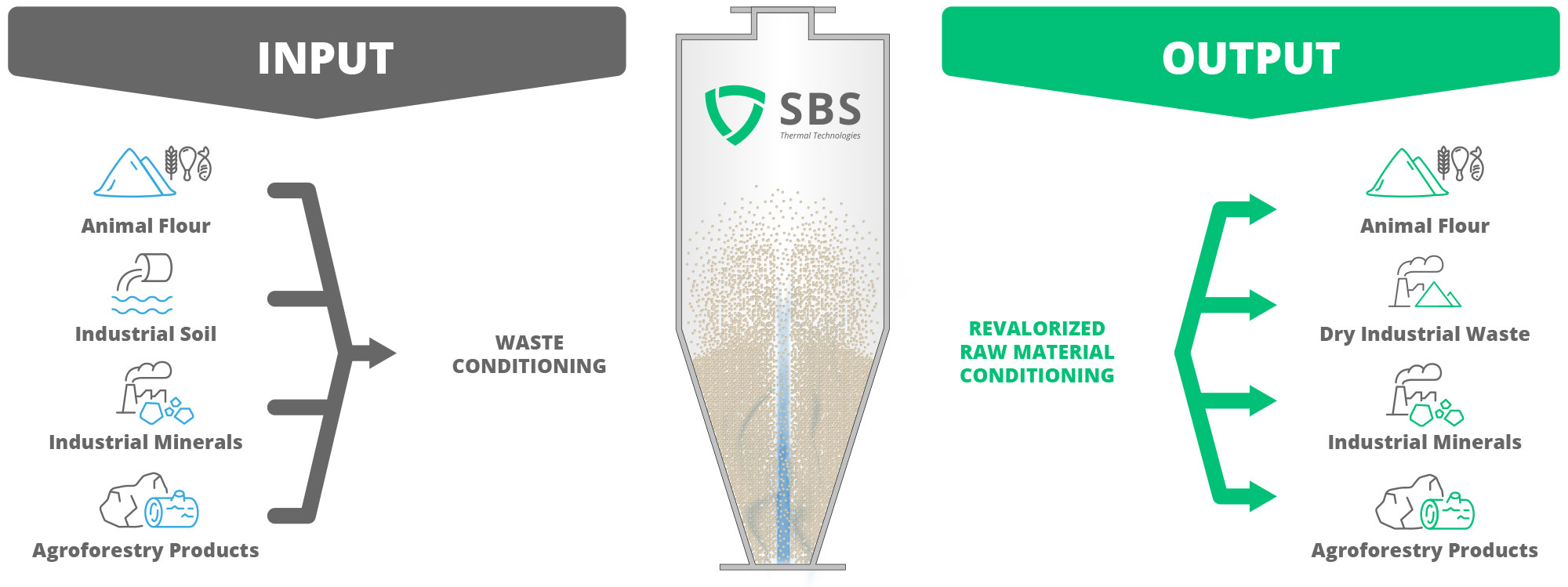

If this sludge is treated using HECO technology the dried waste can be put back into the production chain or sold as raw material for other industries. With HECO it is also possible to treat waste on site in combination with other processes such as combustion or pyrolysis, to eliminate organic content completely and increase the saleability of the resulting product.